Thermography is an imaging technique using infrared (IR) cameras to measure surface temperatures of objects. Infrared cameras use infrared radiation in the same way that a common camera creates an image using visible light. People and objects release radiation as a function of their temperature. Thermal imaging cameras can pick up this radiation and use it to create an image, even in complete darkness! Since the image was created with thermal radiation, the IR camera can detect the temperature of the object it is capturing.

There are many commercial uses for thermal imaging, including military and defense, agriculture, building inspections, automotive, quality control, non-destructive testing, meteorology, and more. With the emergence of the COVID-19 pandemic across the world, another practical application for thermal imaging cameras has become popular: patient screening.

The idea to use infrared imaging technology to screen patients is not new; during the SARS outbreak in 2003, thermal imaging cameras were used to test patient skin temperatures. But it is very important to note that infrared cameras are not effective to actually determine if someone is infected with COVID or any other disease! The cameras are not used to diagnose individuals. Instead, the technology is used as a screening tool for signs of Elevated Skin Temperature (EST). Elevated Skin Temperature is a potential sign of infection or illness. Once an individual is determined to have elevated skin temperatures, they can be further screened by medical professionals using additional tools such as COVID test kits and thermometers. Screening patients in this way saves medical professionals time and resources and increases worker and patient safety due to the quick, hands-off approach! In fact, infrared cameras are already being used in airports, hospitals, and other essential locations to screen individuals for elevated skin temperature. However, not all IR cameras are able to effectively screen individuals for EST.

Only some of the infrared cameras on the market today have the adequate thermal resolution, measurement accuracy, and preparation and scanning methodology to properly detect elevated skin temperatures. For a thermal imaging camera to be used as a medical device, the manufacturer must apply for and obtain an FDA device marketing authorization for the product. FDA approval ensures that the thermal imaging technology has the accuracy, resolution, and settings to properly determine if an individual has EST. In fact, some IR cameras have patient screening modes that trigger alarms when elevated skin temperatures are detected. These patient screening modes can be quite comprehensive! Using the patient screening modes, an average skin temperature can be calculated using actual data from the testing location and updated throughout the day as temperatures and environmental conditions fluctuate.

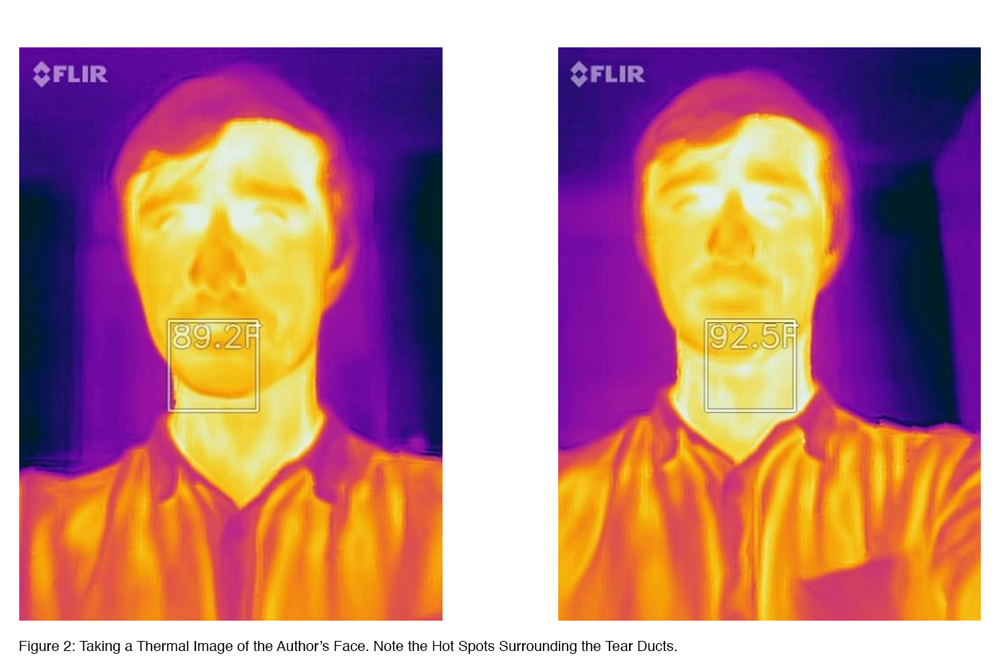

As one can see, thermal imaging technology has obvious practical applications in the medical field. But to obtain accurate results, certain procedures and considerations must be followed. First, individuals must be screened one at a time to prevent skewing results. The individual being screened should be as close as practically possible to the camera based on the lens and focal length of the device. To comply with social distancing guidelines in place by the Center for Disease Control (CDC) and World Health Organization (WHO), the camera operator may opt to use a telephoto lens. When screening an individual with a thermal imaging camera, the temperature reading should be measured at the tear ducts of the eyes. The tear ducts provide the closest temperature correlation between the human surface and core body temperatures and provide the most accurate results. Following these procedures will generate accurate temperature readings, provided the camera has been set up properly.

Similar to common visual cameras, infrared cameras have many settings that must be correctly set up to obtain reasonable results. This includes focusing the camera, selecting a suitable temperature range and color palate for testing, defining and changing the measurement parameters, and performing non-uniformity corrections to ensure the temperatures recorded are accurate throughout the entire screening operation. Due to the involved setup and calibration process, many manufacturers recommend that thermal camera operators obtain, at minimum, a Level One Thermal Imaging Certification through a certified thermography course. With a certified and knowledgeable operator, temperature measurements can be taken from below zero to over three-thousand degrees Fahrenheit with an accuracy of plus or minus two percent! Using the patient screening mode, accuracies of plus or minus 0.9 degrees Fahrenheit can be achieved by using the camera in a stable environment and constantly updating the reference samples that individual readings are compared against.

Even if the cameras are not being used to screen for COVID-19 patients, having a correctly calibrated thermal imaging camera and properly trained and certified operator is essential to obtaining accurate readings for your commercial thermal imaging work. Innovative Engineering Inc. (IEI) uses infrared products to perform condition assessments and building façade inspections. This includes handheld and drone mounted thermal imaging cameras. Employees at IEI have Level One Thermal Imaging Certifications from the FLIR Infrared Training Center. This certification ensures our employees are very familiar with the products and best practices involved with thermal imaging, including drone-based thermography. If you have any questions about how your project might benefit from thermal imaging technology, feel free to reach out to the authors directly or using the “Contact” page on our website

Scott L. Weiland, PE, is a Principal with Innovative Engineering Inc. and sUAS Level One Thermal Engineering Certificate Holder. He can be reached at SWeiland@ieiusa.com

Ethan J. Barrentine, BSCE, EIT, is a Project Engineer with Innovative Engineering Inc. and an FAA Certified Remote Pilot. He can be reached at EBarrentine@ieiusa.com.