Parking Structure Maintenance

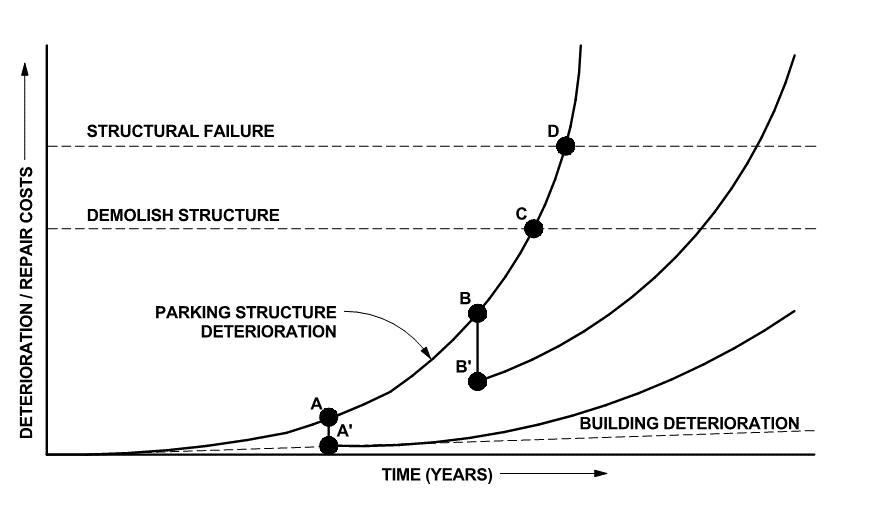

Most people, including professionals in the commercial property industry, are either unaware or refuse to accept that parking structures require maintenance. The truth is, they begin to deteriorate before they are open to the public and do so exponentially after just a few years. Unlike the structure of the building or buildings they serve, which exist in a controlled environment, parking structures are exposed directly to the elements. Exposure to precipitation, road salt, thermal expansion and contraction, and vibratory loads, all contribute to the exponential degradation of a parking structure. As can see in the graph below produced by the National Parking Association, simply kicking the maintenance can down the road only results in higher maintenance costs. You will notice that performing maintenance early at A to A’ costs less than performing it later at B to B’. And delaying maintenance too long can result in an unsafe structure or worse, failure.

Biggest bang for your buck

The top level of your parking structure typically serves as the roof of the facility. Focusing on this level will provide the largest return on your maintenance investment. Since water is the number one enemy, causing the largest repair expenses, it is important to remove water from this surface quickly and efficiently. This can be accomplished by managing precipitation runoff from the surface so that it does not have a chance to soak into the concrete or leak through the joints to reinforcing steel below and cause corrosion and spalling of concrete. Maintenance of surface sealer and joint sealant will provide the biggest bang for your buck.

Surface Sealer

The surface of a highway bridge experiences much more wear and tear than that of a parking structure. Extensive research by many states Department of Transportation (DOT) indicates that penetrating Silane Sealer is a good performer and has been shown to last 12 years on bridges. Penetrating silane sealers are vapor permeable thus allowing the slab to dry out while keeping the bulk water out. Silane sealers have been shown to last up to 5 to 10 years in parking structures and cost roughly $1.00/sf to $1.50/sf to apply including surface preparation. Silane sealer is broken down over time from the inside out and is simply restored by a reapplication. By contrast, Traffic Bearing Membranes (TBM), popular due to their wide variety of aesthetically pleasing colors, trap vapor, debond, wear out, and hides cracks. The state DOT study did not include them in their studies. TBM’s require recoating after 4 years and replacement after 8 to 12 years. They also cost $5.50/sf to $6.00/sf to install. Roughly 4 to 5 times the cost of Silane Sealer.

Joint Sealant

The popular precast parking structures have more joints on the horizontal surface or slab than other structure types. These joints are filled with polyurethane joint sealant to waterproof the slab. Unfortunately, polyurethane is an organic material that breaks down when exposed to Ultraviolet (UV) light and needs to be replaced every 8 to 12 years depending on many factors. Fortunately, however, replacing joint sealant only costs approximately $7.00 per linear foot.

Qualified Contractor

The third and most important bang for your buck is to use a qualified contractor. This may sound cliché, but our inspections routinely reveal short-lived previous repairs. Adequate surface preparation, selection of the appropriate repair materials, and the use of approved application methods are the keys to a lasting repair. There is a low barrier to entry into the construction restoration business. And the truth is there are few uniquely qualified restoration contractors in each market. Choose wisely.

Innovative Engineering Specializes in Parking Structure Maintenance

Innovative Engineering helps owners with parking structure maintenance and reducing restoration costs. Unlike most other building systems that are protected by a conditioned building envelope, parking structures are directly exposed to the elements which results in exponential or accelerated deterioration.

Our engineers are glad to walk your facility and let you know about any conditions that require immediate attention. Since the back of IEI business cards contain a crack gauge, you can easily evaluate any cracks within your structure to determine if it is of concern. Give us a call today!