Lafarge Aggregates Plant

Lithonia, GA

Performed structural condition assessment of a fractionated aggregate plant originally constructed circa 1920. The analysis identified damaged deteriorated structural components in need of repair and structural modifications that needed to be engineered and reinforced. These included gravity carrying members that include columns, vertical truss webs and tunnel ceiling slabs, and lateral load carrying members including bracing and connections that have been removed and/or modified. Additionally, recommended the rust be removed and the steel repainted to minimize further deterioration.

Robins Air Force Base, Marine Corps Reserve Center (MCRC)

Warner Robins, GA

Structural design for a new $15.1M, LEED Certified hangar and renovation of Support Facilities. The 40,375 SF hangar includes structural steel long span trusses, floor vibration design, ATFP requirements, and overhead bridge cranes with a design life of over 20 years. The slab design utilizes state-of-the-art concrete mix & joint design, and foundation utilizes mid-depth stone aggregate columns in lieu of deep foundations.

National Gypsum

Duluth, GA

Designed pads for a new silo and compressor, structural steel supports for the bin and new conveyor line and designed a retrofit truck well within the existing plant.

Marine Corps Logistics Base, Central Repair Shop

Albany, GA

As-built structural analysis and design for the replacement of the existing 35 and 75 ton bridge cranes with 100 ton bridge cranes and the addition of (30) 3 ton jib cranes to the center crane runway support columns. The crane runway beams and supporting columns required replacement, and the foundations required enlargement. Additional challenges faced on project included HTRW remediation in the soil and superstructure.

Atex, Inc.

Gainesville, IL

Structural engineering and design of steel frame and load-bearing tilting concrete panels for this 27,000 SF facility which also included a 15 ton overhead crane.

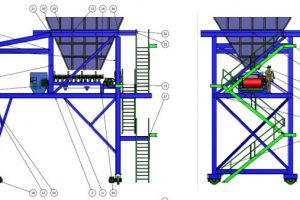

Dos Santos International

Mindanao, Philippines

Structural steel hopper and frame built in Korea for the SM200 Power Station in Mindanao, Philippines. Hopper and frame were designed using STAAD. IEI designed all structural steel for the hopper, the frame, and the connections between the two. The hopper will be used to transport coal from shipping vessels onto ground supported conveyors and was designed to be mobile when the unloading process requires.

Caterpillar Power Systems

Griffin, GA

Structural engineering and design of a 6,500 SF assembly line conveyor addition to the Caterpillar Power Systems Plant. The 421,000 SF plant in Griffin manufactures engines for all Caterpillar Power Systems segments including C9, C15, C18, C32 and 3500 series generator sets, as well as the assembly of the C32 ACERT marine engines.